Types of safety

The category of safety has been divided into 5 parts based on the awareness of the threat to a person. Whose complete information is given below.

1. Ear Protection

When the sound volume reaches 90dB or more, listening to it can cause hearing loss. To avoid this, the efficiency of the equipment used should be known in advance. The symbol used for ear protection is shown in Figure (1.22). The tools to prevent hearing loss are as follows.

(a). Ear Plugs:

It’s made from plastic, rubber, glass or a mixture of all these. If these are properly placed in the ears, they reduce the sound power by 25-30dB. These are of both stable and unstable types. Before using them. It can provide protection from noise of 105-120dB. Ear plugs made of polymer are very good and do not cause pain and strain in the ears.

(b). Ear Defenders :

It covers entire ear and it can reduce the sound range by up to 50dB. It is not advisable to use them when the environmental temperature is high. When glasses or goggles have to be worn while working, it becomes very difficult to use them. It provides protection from sound in the range of 130-135dB.

Also Read: About About Fire Extinguisher

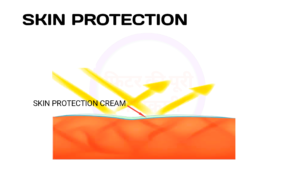

2. Skin Protection

Various chemical ingredients are used to protect the skin which also cause harm. Acid, alkaline, chromate, di-chrome, formaldehyde are present in these chemical components. Normal fat is removed from the skin with the help of paraffin and trichloroethylene. Various types of creams are available for skin protection which are used according to the purpose. All of these provide protection even in mild environments. The cream is applied before working.

Also Read: Personal Protective Equipment (PPE- PERSONAL PROTECTIVE EQUIPMENTS)

3. Respiratory Protection

Use of Respiratory Protection Equipment (RPE) is essential for workers working in places with dust, smoke, excessive amounts of toxic and soil. Selecting the appropriate RPE is actually very complex. We can use face masks everywhere except in places with low concentration of molecular fluid.

(a). Nominal Protection Factors

BS4275 is used for selection of RPE, which is called NPF. Different facts are used for different types of instruments. NPE measures the theoretical capacity of the RPE. Concentration of contaminated particles in the environment NPF = Concentration of contaminated particles on the face.

(b). Forms of Respiratory Protection Equipment :

Respiratory protection equipment’s are of the following types:

(i). Face Masks:

These are devices which remove non-toxic paint spray and dust particles from the nose and mouth and make them useful for breathing. They are unable to protect against toxic and disaster particles.

(ii). General Purpose Respirators:

These are a form of ori-nasal face mask with a filter to separate liquids and solids.

(iii). Positive Pressure Power Respirators:

This is an ori-nasal face mask in which a flexible hose is attached to the power driven pack. These are more effective than ordinary respirators. Under these, better filters are used which are operated with positive pressure. These are of three types

- complex semi mask respirator

- heavy cartbridge aspirator

- Front and rear mounted canister gas mask:

(iv). Positive Pressure Respirator with Helmet:

This form of respirator protects the head, nose, eyes and lungs. This respirator makes the dusty air pass through the filter. Semi-filtered air is delivered to the fine filter bag. This filtered air provides cool air to the entire oral area. Finally this air is sent to the bottom chamber with the prescribed rate. The value of this rate is such that dust particles cannot enter our mouth or nose. It also includes a battery which provides low voltage electrical power. This battery is portable, which can be carried in belt or pocket.

(v). Gas Respirators:

There are two types of gas respirators – cartbridge and canister

- Cartbridge gas respirator is similar to dust respirator. A chemical cartridge filter is used in it, it is able to provide protection only from low concentration non-toxic gases or up to 100 PPM concentration, on the other hand,

- canister respirators are manufactured with the aim of providing protection from more concentrated toxic gases. Special types of chemical filters are used for this purpose.To remove dust particles from it. Special filters are also used.

(vi). Emergency Escape Respirator:

These respirators are specially designed to protect people in emergency situations. These are used for short periods of time and are not used for general security.

(vii). Air Line Breathing Apparatus:

In this apparatus, a source of pollution-free air and compressed airline is used. It is a full mask or semi-mask attached to a flexible hose. It can be used in any polluted area but the length of its air line is limited. To use fresh hose, a pump of 10 m length is required.

(viii). Self Contained Breathing Apparatus (SCBA):

This apparatus allows for free movement because the user himself holds the supply of breathing air. There are three types

- Demand Type Compressed Oxygen Compressed Air Respiratory Equipment

- compressed oxygen recirculation respiratory equipment

- oxygen production type

This device can be of both open and closed circuit type. In open circuit, air is supplied through a lung operated demand valve or hose. In this, the hose is connected to the compressed air kept near the user. Purifier is used to remove CO2 in closed circuit. The purified air obtained from this purifier is mixed with oxygen and sent back to the respirator. Both these devices are used in dangerous atmospheric and oxygen deficient conditions.

Types of safety

Also Read: Types of Tools

Types of safety

4. Critical Points for Respiratory Protective Equipments

- The points to be kept in mind for respiratory protective equipment are as follows:

- Use air purifier equipment if the level of polluted particles is less than 2% by volume and chemical cartbridge if it is less than 0.1%.

- Use RPE with a helper at work.

- Create a system for periodic cleaning and development of RPE. Follow the following procedure for cleaning.

- Remove all filters, canisters, cart bridges, etc.

- Wash the main ingredients with soap and warm water.

- Keep the main ingredients in hot water for 5 minutes.

- Keep this component in formalin or sodium hypochlorite solution for 5 minutes.

- After this wash it with cold water and dry it.

- Use the canister only after having complete information about the color code, nature and life span of the contaminated particles.

- Check for punctures and physical damage.

- Use hose mask in clean environment at a distance of 20 feet.

5. Protection of Body

- There are many safety garments available for body protection which protect us from harmful chemicals, temperature, humidity, soil dust etc.

- Leather aprons protect us from sharp objects, hot chips, rough surfaces or objects etc.

- Asbestos apron – These are used to protect the body from heat.

- P.V. C . apron (P.V.C. apron) – These are used for protection from chemical and acidic substances, paint, coolant etc.

- Lead Apron – These provide protection from X-Rays, Gamma Rays etc. To hurt.

- Safety Belt – People who work at heights greater than 10 feet (2 m) must wear a safety belt. It protects the person from falling from height and prevents accidents.

- Suspension Belt – These are useful where work cannot be done from a permanent surface such as while repairing a pole.

Also Read: Vernier Caliper