pipe and pipe classification in detail 2023

Today in this post you will know what is a pipe, how many types of pipes are there? What is NPS? What is single random and double random pipe? What is the schedule that is spoken in the pipe? I will tell you all these things in detail in this post.

so let’s start

What is pipe?

The pipe is shaped like a hollow cylinder, which is used in the piping system, with the help of which we can take water, oil or gas or steam from one place to another.

Different types of pipes are used in piping system according to its design condition and technical parameters. and what is the temperature for high pressure services, what is the pressure for low pressure utility service? After getting all these things, they decide which pipe to use.

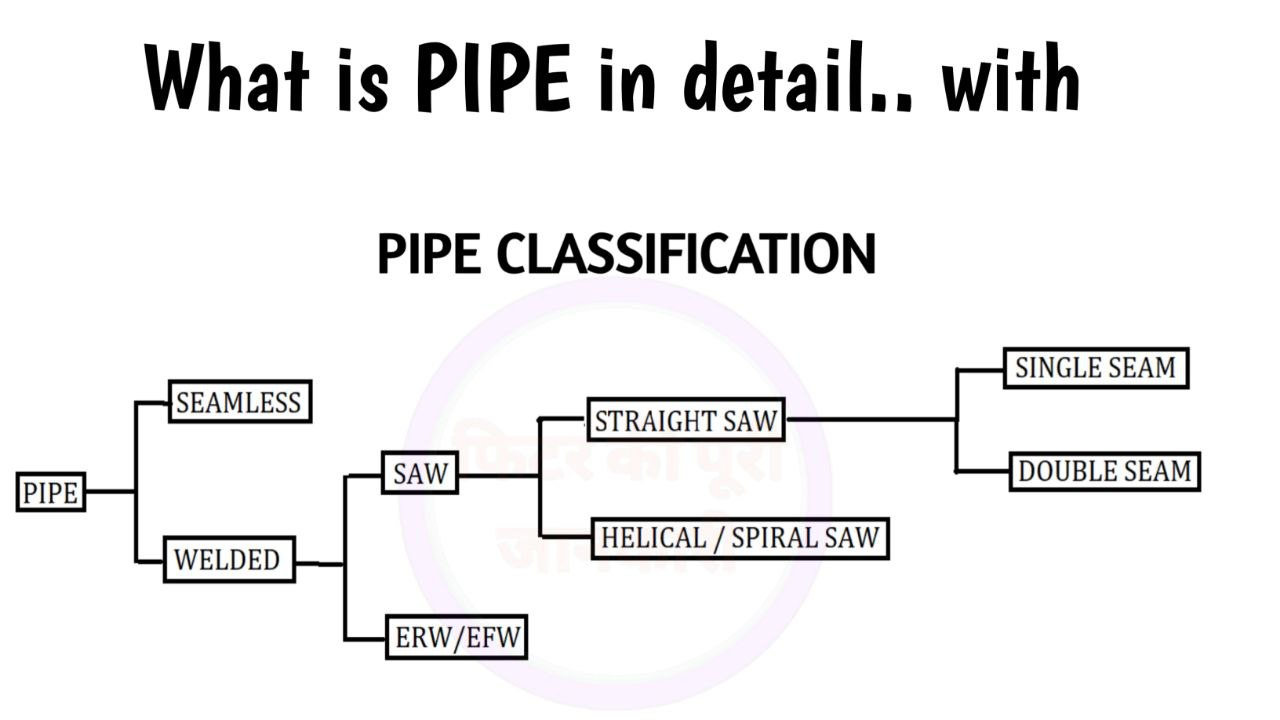

Here you can see in the photo above that there are many types of pipes that are used in piping. You can divide the pipe into two categories. The first category is seamless and the second is welded.

Now you can further divide the welded pipe into two parts like SAW and ERW/EFW

What is SAW?

The full form of SAW is Submerged Arc Welding.

SAW is welding with filler metal!

Read this too… How to make a pipe bend?

What is ERW? What is ERW?

full form of ERW is Electrical Resistance Welding

ERW is welding without filter metal.

What is EFW?

EFW welding can be with filler or without filler.

full form of EFW is Electric Fusing Welding

You can further divide SAW into two parts

Helical spiral saw

straight saw

You can further divide the straight saw into two parts.

Single Seam

double seam

Let us understand from the beginning..

The name seamless pipe itself suggests that there will be no seam in it.

seam means there will be no weld

Seamless pipe is considered to be the strongest

Seamless pipes are used for high pressure and high temperature applications.

Seamless pipes are also the costliest

There is a limitation of seamless pipe that it will be available to you in limited size.

Usually seamless pipes up to 18 inch size are easily available!

If you want seamless pipe above 18 inches then it is very expensive.

Pipes over 18 inches are custom made it means they don’t have to be pre-existing.

Read this too… How to make reducer of pipe?

How do you identify seamless pipe?

You will see the ID of seamless pipe in the inside side or outside side, if you do not see any sim (welding joint) then you will know that it is a seamless pipe. Above is the photo of seamless pipe.

What is ERW pipe?

The full form of ERW is Electrical Resistance Welding.

ERW is a process of welding means it is a method of welding. In the photo below you can see that there is a small sim, which is ERW pipe, if you look in its side, you will see such a small seam, it is trimmed. If you do not trim, then this flush metal would have been another metal here, so that you will easily know that it is ERW pipe only!

If you see in the photo below, you will see the seam in the inside, but if you look outside, you will not know at all, if it is clean, you will see a straight line, otherwise you will not see anything because If there is rust in it, then you cannot identify it easily, but if you look inside, you will easily know that it is ERW pipe only.

What is EFW pipe?

The full form of EFW is Electrical Fusion Welding.

EFW pipe, if it is welding without filler, then you will see ERW pipe from inside and outside like this.

But if it is welded with filler metal, then you will see a slight seam here and there, that is, it comes because of the welding of filler metal.

What is SAW pipe?

The full form of SAW is Submerged Arc Welding.

There are two types of SAW: 1. Helical or Spiral SAW 2. Straight SAW

What is Helical or Spiral SAW?

These spiral SAW pipes are normally used for low pressure applications and one of its biggest benefits is that you can make any size if you need a very large diameter means 1.2 meters or up to 2 meters dia. The pipes that are made can be made by the Submerged Arc Welding process!

What is Straight SAW?

The seam of SAW pipe is bigger than the seam of EFW pipe or it can be said that it is thicker, when you look, you will know that this is SAW pipe, if you look at its inner side also, you will see the same. If you will see similar big sim on the inner side as well, then you have to understand that it is the pipe of Strat SAW!

It has two types: 1. Single Seam 2. Double Seam

What is Single Seam?

If the pipe is of small diameter, then it can be made by rolling it in a single plate, so that only one seam means only one welding will come, then it will be called single seam!

Read this also… How to make T branch of pipe?

What is Double Seam?

Double seam means if you are making large diameter SAW pipe, then you cannot roll the entire pipe in single plate, for that you have to make it in two or more parts, so that the number of seams will also increase, then it will be called double seam. !

Even then you have come to know how many types of pipes are used in piping and how to identify them all.

So let’s go ahead now if you are working in the industry then you must have heard NPS is inch system, in this you two inch three inch four inch such NPS size is defined

What is NPS?

The full form of NPS is Nominal Pipe Size.

Pipe size is defined in NPS!

NPS is written in inches like NPS 2″, NPS 3″ etc..

If you check the pipe size up to 1″ – 12″ and its OD, it will not be equal to its size, that means the OD of one inch pipe will also not be one inch!

The OD of a 12 inch pipe will not be 12 inches, it will be a little more than 12 inches and if you check its ID, it will be less than 12 inches! So this is what you have to keep in mind in NPS.

You have to keep these two things in mind that the OD of the pipe up to 12 inches will be more than its size and the size above 14 inches will be its OD.

But when you see a pipe of more than 14 inches, then its outside diameter becomes equal to the size! Below we have given its chart, you can see it or download PDF too!

| NPS | OUTSIDE DIAMETER (IN & MM) | INSIDE DIAMETER (IN) | WALL THICKNESS (IN) |

|---|---|---|---|

| 1/8 | 0.405″ or 10.28 mm | 0.269″ | 0.068″ |

| 1/4 | 0.540″ or 13.71 mm | 0.364″ | 0.088″ |

| 3/8 | 0.675″ or 17.14 mm | 0.493″ | 0.091″ |

| 1/2 | 0.840″ or 21.33 mm | 0.622″ | 0.109″ |

| 3/4 | 1.050″ or 26.27 mm | 0.824″ | 0.113″ |

| 1 | 1.315″ or 33.4 mm | 1.049″ | 0.133″ |

| 1¼ | 1.660″ or 42.164 mm | 1.380″ | 0.140″ |

| 1½ | 1.900″ or 48.26 mm | 1.610″ | 0.145″ |

| 2 | 2.375″ or 60.32 mm | 2.067″ | 0.154″ |

| 2½ | 2.875″ or 73.02 mm | 2.469″ | 0.203″ |

| 3 | 3.500″ or 88.9 mm | 3.068″ | 0.216″ |

| 3½ | 4.000″ or 101.6 mm | 3.548″ | 0.226″ |

| 4 | 4.500″ or 114.3 mm | 4.026″ | 0.237″ |

| 5 | 5.563″ or 141.3 mm | 5.047″ | 0.258″ |

| 6 | 6.625″ or 168.27 mm | 6.065″ | 0.280″ |

| 8 | 8.625″ or 219.07 mm | 7.981″ | 0.322″ |

| 10 | 10.750″ or 273.05 mm | 10.020″ | 0.365″ |

| 12 | 12.75″ or 323.85 mm | 11.938″ | 0.406″ |

| 14 | 14.000″ or 355.6 mm | 13.124″ | 0.438″ |

| 16 | 16.000″ or 406.4 mm | 15.000″ | 0.500″ |

| 18 | 18.000″ or 457.2 mm | 16.876″ | 0.562″ |

| 20 | 20.000″ or 508 mm | 18.812″ | 0.594″ |

| 24 | 24.000″ or 609.6 mm | 22.624″ | 0.688″ |

What is DN?

DN is identified in millimeters!

What you have to remember here is that the outside diameter of the pipe is fixed. For any size, if the thickness of your pipe increases, then your internal diameter will decrease.

Read this also… Important measurement?

Pipe Length :

If you are ordering pipe, then you can order by defining single random and double random means what is the logic of defining this?

Means the seamless pipe is made in billets. Pipes made from billets are not all of the same size, some pipes are small and some are big, and where the pipe is going to be used, they are not all of the same size, there are no pipes, even there you will get small and big pipes. If there is an as on requirement then it is a system in the code to solve the problem of both manufacture and purchase.

Single Random & Double Random If you order single random pipe, you will get pipes ranging from 4.82 – 6.7 meters and 5% of that length will be 3.7 to 4.8 meters. And the average of the double random pipe will be 10.7 meters!

These short are single random pipe they are short and double random pipe are long so according to your requirement you can order pipe you can order pipe in fixed length but it will cost you more It will happen because what will happen in that is that the manufacturer will have to discard the small pipes. So that’s it, some information about the length of the pipe.

What is Pipe Schedule?

The thickness of the pipe i.e. the thickness of its wall is expressed in the schedule number. Wherever you go, you will get to hear that 4 inch schedule 60 pipe or 4 inch schedule 40 pipe or 6 inch schedule 80 pipe, then this schedule number is the thickness of the pipe, as the number increases Will go, the thickness of your pipe will increase!

The thickness of the pipe of 5 schedule thickness will be less and schedule 160 which will be the thickest pipe and you must have seen the second alternative which is standard or extra strong or double extra strong. This system is ion pipe system, it is an old system, but you will find pipes of its size in the schedule number.

Here you have to remember that more schedule means more thickness

What is Schedule Number?

The schedule number is a random number that drives the equation 1000 × P/S from this number. Here P is service pressure and S is Allowable Stress.

So by taking the value of both Service Pressure and Allowable Stress and keeping it in the formula according to the material, you can drive the schedule number.

What is 5S 10S 40S and 80S?

5 and 5S both are not beans 5S 10S 40S and 80S Wherever you see this S, you have to understand immediately that this pipe is stainless steel i.e. SS pipe!

This is an ASME Code, according to ASME B36.19, the schedules of stainless steel means its thickness has been defined and there are only four schedule numbers in it, which I have mentioned here, so you can see anywhere. So you should understand that these are steel pipes and 10 and 10S are not the same.

What is Dimension Standard?

According to the dimension standard given in B 36.10 for carbon steel pipe, the size covered in it is from 1/8 inch to 80 inch!

ASME B 36.19 for stainless steel pipe is given and this standard covers dimensions from 1/8 inch to 30 inch pipe.

Read this also… Types of Crane?

Pipe ends?

pipe ends which are there are of different types if you are doing socket welding then your pipe end will be plain end here you can see it is plain

These are used for low pressure and low temperature applications such as water supply in utility service, air supply etc.

The most commonly used pipe end is the Bevel End where you do butt welding!

There is a threaded end, which is threaded, it is also used for low pressure end and low temperature applications.

Spigot is also a type of pipe end but it is not so popular, maximum you will see these three ends in the industry!

I hope you got to learn something from this post, if yes then give a like and share it with your friends, then see you in the next post.. Thank you

Download App Pipe fitter book